About LGSF/CFS Building Construction

Steel is widely used in the construction of multi-storey buildings. However, steel construction is seldom used and is traditionally considered uneconomical for landed properties. In many parts of the world, timber, structural brickwork and reinforced concrete construction is usually preferred for landed properties.

Over the years, various improved systems have been developed for use in landed properties. An economical light gauge steel frame system is increasingly being used in America, Europe, Australia and New Zealand. This light gauge steel frame is developed through a cold-formed process without the use of heat. This process enables steel manufacturers to produce light-weight but high tensile steel sheets. The sheet surface is coated with a zinc alloy that completely covers the steel surface and seals it from the corrosive action of its environment. This results in buildings that are more solid, rigid, stronger, durable and easier to build.

CHARACTERISTICS OF THE LGSF SYSTEM

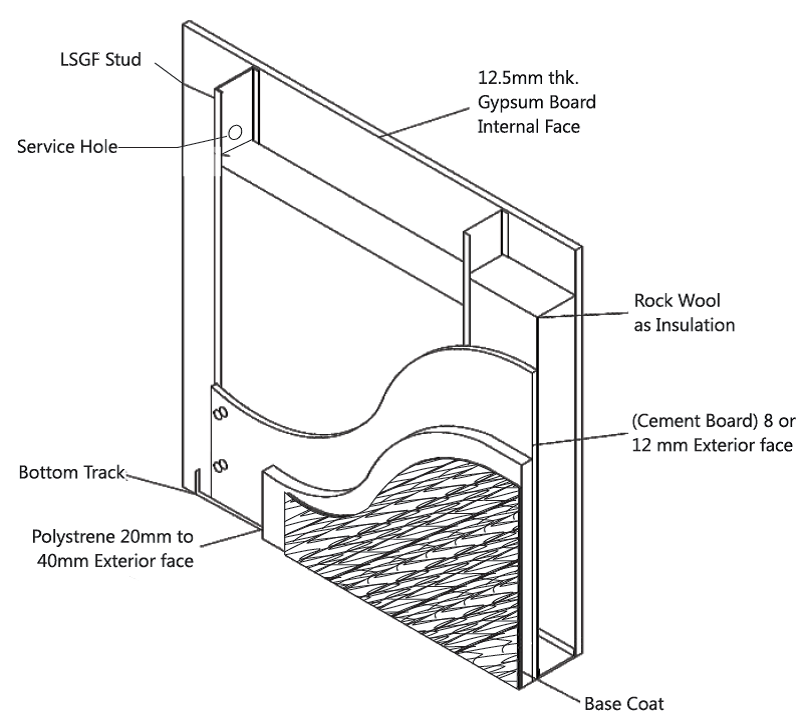

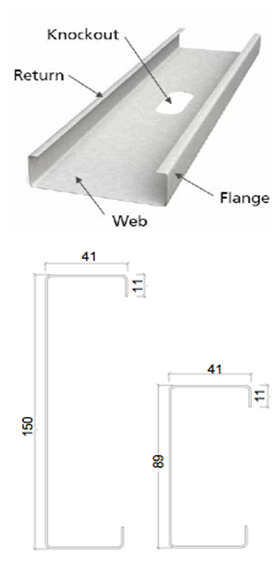

- The light construction LGSF frame is assembled from cold formed galvanized steel profiles. In the gaps between the elements of the frame heat insulation material is placed and the frame is supplied with surface layers made of various materials, forming a layered structure.

- Generally, the elements of the frame structure are constructed of C profiles with a dry, assembly style building technology. Numerous steel fasteners, stiffeners and other complementary profiles are connected to the basic elements of the structure.

- The applied materials filling the gaps between the elements of the frame not only perform heat insulation, but also meet acoustical requirements and they are an efficient fire protection tool.

- The steel is hot-dipped galvanized with a minimum Z220 coating for load bearing applications and non-load bearing applications. Alternatively, steel hot-dipped in Alum/Zinc coating (known as Galvalume with 55%Aluminium and 45%Zinc) is also used. The applicable codes are ASTM A653 for galvanized and ASTM A792 for Galvalume. The light gauge cold-formed steel structural members are designed as per AS/NZS 4600:2005 and AISI S100.

- The Results of various Tests and Studies conducted on the material coatings in different atmospheric conditions state that there is a loss of only 1-2% of the coating over a period of 10years even in test locations as close as 10m from the coast.

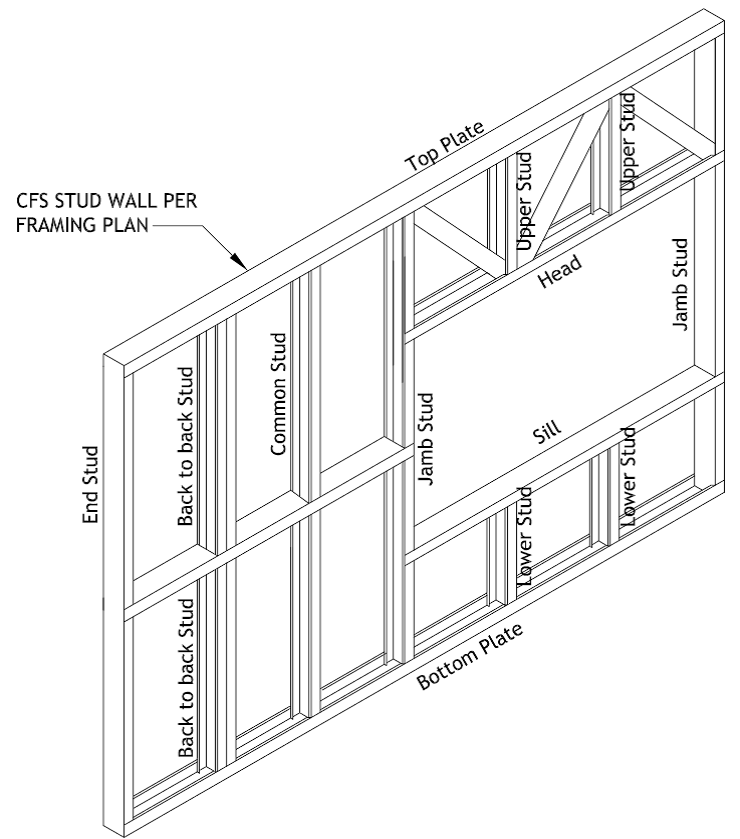

Load Bearing Wall Panels

A load bearing wall is one which carries vertical loads from the construction above and lateral loads resulting from the wind as well as seismic forces. These loads may act separately or in combination. Both internal and external walls may be load bearing. The resultant impact is far better as compared with any conventional structure.

MIPL LSF System recommends the following for the load bearing walls

- All load bearing studs shall be minimum G550 cold formed steel of 0.75mm thick C 89 section. The thickness of section will vary from 0.75 to 1.6mm thick depends on the loading requirement.

- A structural top track is used to carry truss loads from the roof to the studs, where the studs are not located directly under the truss load points. Top track shall be G550 cold formed section. The top track shall be secured transversely by incoming trusses or rafters with approved wall support brackets.

- The bottom track must be fully supported under every load-bearing stud. This is critical with studs beside openings, or studs carrying major loads for the roof, ceiling or upper floor construction. The support can be provided by a floor joist, blocking piece located directly under the stud.

- Lintels are needed for openings greater than 1200mm of load bearing walls. Lintels under sheet metal roofs are principally designed for uplift from wind loading on the roof structure while lintels under tile roofs are designed principally to support downward loads from the roof trusses.

- Noggings in the form of a notched plate may be used in load bearing walls to provide lateral restraint to the wall studs.

- Bracing is needed in certain walls to provide racking resistance against wind load. It could be in the form of bracing straps or bracing sheets depending on the requirement.

- The studs, joists and trusses must be properly aligned in order to transfer the loads to the member below.

Non-Load bearing Wall panel

Internal walls which do not support truss loads are considered non-load bearing.

MIPL system recommends the following for non-load bearing walls

- Studs for internal non-load bearing walls shall be minimum Light gauge steel G550 C89, 0.75mm thick cold formed section.

- Top plate shall be fixed to trusses to provide lateral stability for the wall. The connection shall not transmit vertical loads to the wall.

- The bottom track shall be minimum G550 cold formed section

- Angle lintels are not required for openings in non-load bearing wall frames.

- Noggins is generally not needed for internal non-load bearing walls unless noted otherwise